Dampers

Brigham Larson PianosShare

The damper system on this 1883 Steinway C was in a completely unusable shape when they arrived at the shop. The dampers would wobble uncontrollably when played and couldn’t be securely held by the underlevers (1). The first problem was fixed by rebushing the damper guide rail, which is screwed to the front of the soundboard and supports the damper wires close to the strings. Once the old bushings were removed cloth of varying thicknesses was tested until the wire was supported enough to not wobble but also with no friction. That cloth was then pulled through, glued, and cut with a caul that held it against the wood while the glue dried (2).

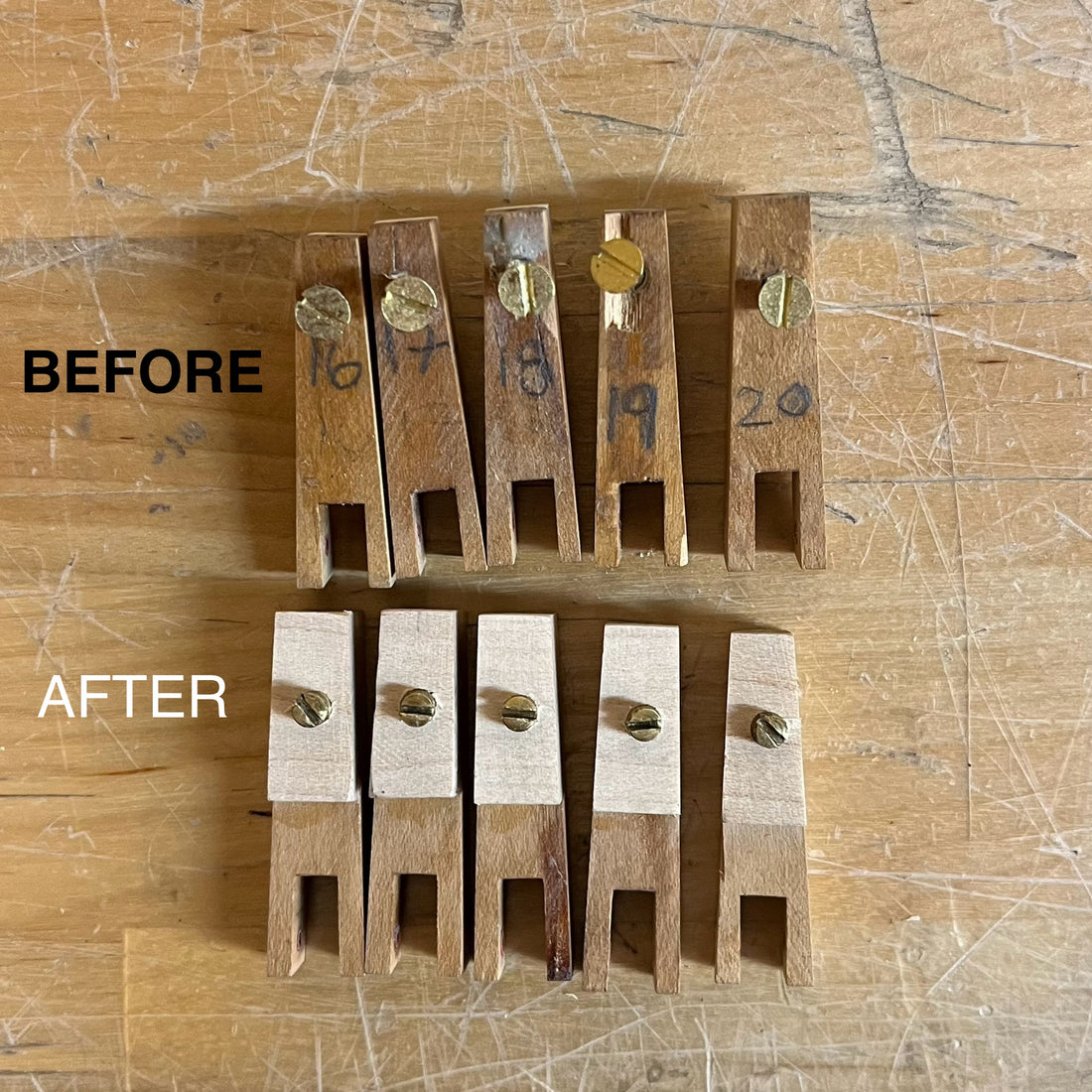

Next, the damper blocks were separated from the damper levers. The levers had their loose support springs reglued (3) and the blocks were sanded before gluing shims to the front (4) to give more material for the new grub screws to thread into (5). Once the glue was dried a chisel was used to remove the bulk of the excess material before the shims were sanded perfectly flush to the blocks (6 & 7) and got a pilot hole (8). The grub screws were then threaded in until they held their wire securely, then backed out a half turn so the wire could be removed and the blocks were repinned on the levers (9 & 10). After all of that the damper system is finally ready to be put back in the piano and regulated.

1.

3.

4.

6.

7.

8.

9.

10.

Submitted by Adeline Bouwhuis (BLP Shop Technician)